By: Mark Keyser – Sr. Mechanical Engineer

Client: Energy Storage Solutions Company

Re:Build AppliedLogix was tasked with developing an electronics enclosure solution that structurally supports itself and enclosed PCBAs while assembled between end units of an advanced energy conversion stack. Allowance for variance in stack length that results from the large stack up of tolerances from the repeating element parts (plates, membranes, and seals) was also a key design requirement. The enclosure needed to withstand the temperature and vibration imparted by the system while shielding the electronics from inadvertent water vapor and stack coolant leaks. The solution also had to allow the user to make needed stack electrical connections to the enclosed PCBAs while assessing its working status without removing the enclosure cover. Cost targets were critical at low volume (10’s) as well as at higher volume (1000’s) with a common, scalable design strategy.

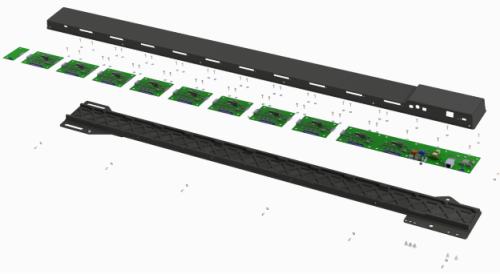

The solution included a custom ABS enclosure base and cover that protects the electronics from the environment in and around the stack. The housing base has mounting features that allow for easy customer integration to the stack structure and provides adjustable mounting at one end to accommodate assembly variation.

SolidWorks was leveraged first to determine all of the connector positions and then establish the initial board layouts that were further populated and routed by the AppliedLogix board layout group. Next, the enclosure was designed around the boards with manufacturing options and respective process requirements in mind. 3D models were generated to communicate design intent and once agreed upon by the customer and supplier, detailed manufacturing prints were created.

All electrical and communication connections can be made without opening the enclosure and have integrated strain reliefs at both mounting flanges. LED indicators provide operational status to the user through apertures in the cover of the assembly.

The design is able to be machined or 3D printed at lower volumes and uses conventional fasteners for assembly. The enclosure’s modular design was also tooled using thermoformed components in support of higher volume production. An optional heat staking feature for board attachment was included in the design to reduce fasteners and decrease assembly time as production volumes scale.

Let’s talk about your unique challenges and how Re:Build AppliedLogix can help you.